- HTAC

- Regenerative burner requiring reversing fuelIntegral self-regenerative burnerRegenerative with non-reversing fuelRegenerative burnerTop mounted integral regenerative burner

- Complete set of industrial furnace

- Aluminum melting furnace seriesTilting reflector furnaceRegenerative tilting furnaceRegenerative type crucible furnaceRegenerative type shuttle kilnRegenerative type organic waste gas incinerator

Regenerative requiring reversing fuel

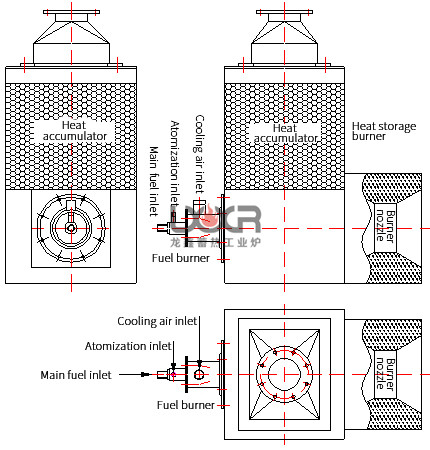

The regenerative requiring reversing fuel is composed of heat storage burner, fuel burner and heat storage body, the fuel burner is arranged in the middle of the heat storage burner and adopts the structure that two independent heat storage type burners are arranged in pairs.

The regenerative burner requiring reversing fuel designed and manufactured by Guangzhou Longxin Heat Storage Industrial Furnace Co., Ltd. includes LXQ-I series gas heat storage type burner, LXY-I series fuel heat storage type burner, LXYQ-I series oil/gas dual-purpose heat storage type burner, and LXKM-I type air-coal gas double-preheating heat storage type burner, altogether four varieties.

-

- Product features:

1.Energy-saving and emission reduction: improve the energy-saving effect, dilute the combustion-supporting air, reduce the NOx generation, and solve the problems of energy consumption and environmental protection;

2.Fully automatic operation: each gas burner can be provided with ignition and detection device without the need of setting ignition burner additionally, the ignition and temperature rising of the furnace body are convenient, and the on-duty small burner can be installed for the gas burner according to the requirement, so that the low-temperature section combustion is stable and reliable, and fully automatic operation can be realized;

3.Strong flexibility: not only the heat storage burners are set in pairs. The position can be set according to the site environment and the combustion technology of different industrial furnaces. In addition, the heat storage burner unit can be set with independent direction reversing control, and one or more units can be installed according to the size and needs of the kiln.

-

- Product parameters:

Combustion capacity: 115 - 4000kW;

Applicable fuels: gas, fuel, oil and gas;

Suitable conditions: the furnace temperature is above 800 C, and the fuel / gas ensures that the energy saving rate is higher than 25%.

Application occasions: The regenerative burner with fuel to be reversed is suitable for high temperature industrial furnaces with low temperature control accuracy, low requirement for combustion atmosphere and low requirement for fluctuation of furnace pressure.

Illustration: structure diagram of the regenerative burner requiring reversing fuel

For further information, please contact us. We will serve you wholeheartedly!

13719286088(WeChat)

13719286088(WeChat)

粤公网安备 44011102000800号

粤公网安备 44011102000800号