-

home

-

about

-

news

-

products

Aluminum melting furnace series

- Regenerative aluminum melting furnace and heat preservation furnace

- Double chamber side well aluminum melting furnace

- Tilting rotary furnace

- Tilting reflector furnace

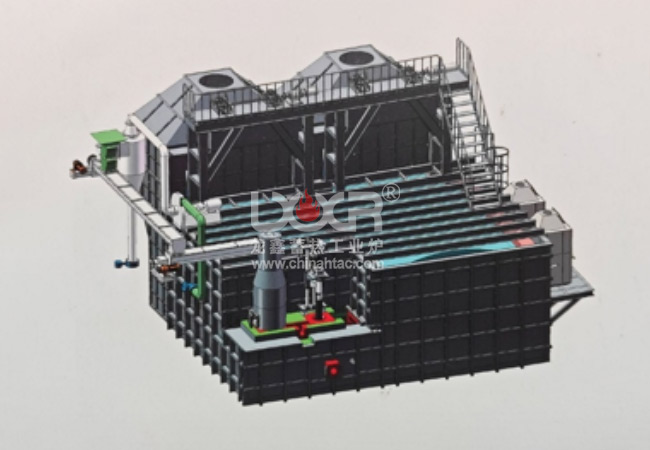

- Fixed type regenerative aluminum melting furnace

- Regenerative double chamber melting furnace

- Side well aluminum scrap furnace

- Continuous automatic feeding rotary furnace

- Regenerative type crucible furnace

- Regenerative type shuttle kiln

- Regenerative type organic waste gas incinerator

Aluminum water pump series

HTAC

Aluminum liquid on-line degassing

Industrial furnace accessories

-

Technology

-

case

-

contact

Substantial price

Substantial price Profound technical strength

Profound technical strength Excellent product quality

Excellent product quality Quick after-sales service

Quick after-sales service

粤公网安备 44011102000800号

粤公网安备 44011102000800号