- HTAC

- Regenerative burner requiring reversing fuelIntegral self-regenerative burnerRegenerative with non-reversing fuelRegenerative burnerTop mounted integral regenerative burner

- Complete set of industrial furnace

- Aluminum melting furnace seriesTilting reflector furnaceRegenerative tilting furnaceRegenerative type crucible furnaceRegenerative type shuttle kilnRegenerative type organic waste gas incinerator

- Industrial furnace accessories

- Aluminum liquid circulation mechanical pump/lifting pumpAluminum liquid lifting vacuum pumpLongxin burner controllerLongxin regenerative burner type combustion system control softwareTwo-position three-way selector valveLongxin high-quality ignition gunFuel oil gunBall-blocking brickMechanical pressed regenerative burner bodyFurnace door and accessories

Integral self-regenerative burner

The integral self-regenerative burner is also composed of heat storage burner, fuel burner, heat storage body and so on, and the periphery of the single fuel burner is uniformly distributed with 3-9 heat storage burners, so as to form an integral structure, which is similar to the flame shape of conventional burner.

The integral self-regenerative burner designed and manufactured by Guangzhou Longxin Heat Storage Industrial Furnace Co., Ltd. includes LXQ-III series gas heat storage type burner, LXY-III series fuel heat storage type burner and LXKM-III type oil-gas double-purpose heat storage type burner, altogether three varieties.

- Product features:

1.Integral self-regenerative burner integrates all the advantages of the regenerative burner requiring reversing fuel and regenerative burner with non-reversing fuel, and features compact structure, the size is greatly reduced, the combustion capability is not large, and the manufacturing cost is low.

2.The combustion is stable and reliable, and the hearth temperature has low fluctuation;

3.The air/flue gas reversing is stable, the hearth pressure fluctuation is small, which can thoroughly solve the operation problem of unstable high hearth pressure under heat storage combustion.

- Product parameters:

Combustion capacity: 50-600kw;

Applicable fuels: gas, fuel, oil and gas;

Suitable conditions: the furnace temperature is above 800 C, and the fuel / gas ensures that the energy saving rate is higher than 25%.

Product application: It is very suitable for high temperature industrial furnace with high temperature control precision, strict firing atmosphere and low pressure fluctuation.

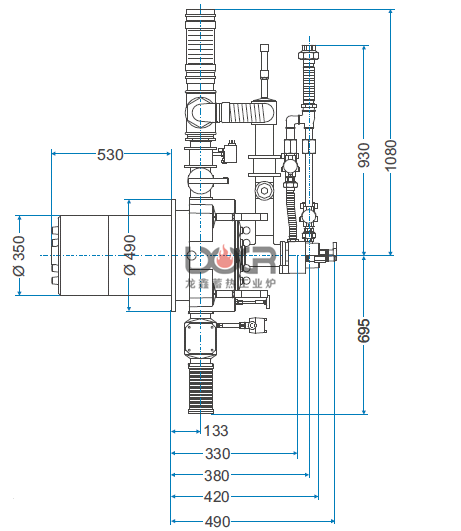

Illustration: Top view of 200kW integral self-regenerative burner

For further information, please contact us. We will serve you wholeheartedly!

13719286088(WeChat)

13719286088(WeChat)

粤公网安备 44011102000800号

粤公网安备 44011102000800号