- HTAC

- Regenerative burner requiring reversing fuelIntegral self-regenerative burnerRegenerative with non-reversing fuelRegenerative burner

- Complete set of industrial furnace

- Regenerative aluminum melting furnace and heat holding furnaceRegenerative chamber type heating furnaceRegenerative type shuttering roasting furnaceRegenerative type heat treatment furnaceRegenerative heat treatment furnaceRegenerative type annealing furnaceRegenerative type shuttle kilnRegenerative type crucible furnaceRegenerative type radiation heating pipeRegenerative type organic waste gas incinerator

Regenerative burner type organic waste gas incinerator

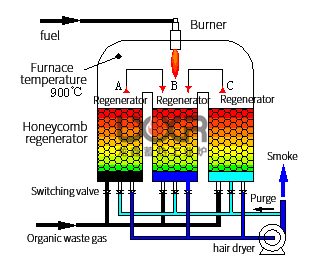

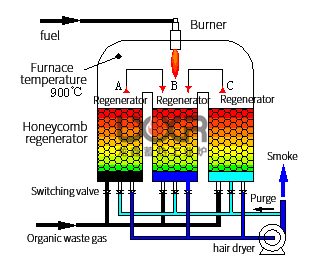

The RTO of regenerative organic waste gas incinerator designed and constructed by Guangzhou Longxin Regenerative Industrial Furnace Co., Ltd. is a kind of organic waste gas treatment equipment developed on the basis of digesting and absorbing foreign advanced technology and combining with our company's advanced regenerative combustion technology. According to the number of regenerative chambers, it can be divided into two-box structure, three-box structure and five-box junction. Structure. Typical two-box RTO consists of a combustion chamber, two ceramic regenerators and two reversing valves; three-box RTO consists of a combustion chamber, three ceramic regenerators and nine switching valves; five-box RTO consists of two combustion chambers, five ceramic regenerators and 15 switching valves.

-

- Product features:

1. Direct heat transfer between regenerator and VOC exhaust gas/purified flue gas has the advantages of fast heat transfer speed, high heat transfer efficiency, high heat utilization rate, low exhaust gas temperature and energy saving;

2. Temperature distribution in furnace is uniform and noise is low, which improves the purifying efficiency of VOC exhaust gas and prolongs the service life of refractories in furnace;

3. Temperature can be controlled and greatly reduced. Local high temperature and high oxygen area in less process can inhibit the formation of NOx and have good environmental protection effect;

4. The system has high automation and the PLC control system can automatically complete many tasks. The combustion system has a complete set of detection and alarm, flameout, cut-off and re-ignition functions to ensure that the furnace is controllable, stable and reliable;

5. According to VOC exhaust gas conditions and customer needs, thermal energy recovery devices can be set up to make full use of the thermal energy generated by VOC exhaust gas incineration;

6. Honeycomb ceramic regenerator with super-high thermal storage capacity. And aluminium silicate refractory fiber lining material, can greatly reduce the volume of incinerator, reduce the area occupied by equipment, do not need to install high chimney exhaust, reduce the cost of construction.

-

- Product parameters:

Applicable fuels: gas, fuel oil;

product application: Incinerator is an industrial furnace for waste incineration, including solid waste incinerator, waste liquid incinerator and organic waste gas incinerator.

Illustration: working principle diagram of two box structure RTO Illustration: working principle diagram of three box structure RTO

Illustration: working principle diagram of three box structure RTO

For further information, please contact us. We will serve you wholeheartedly!

13719286088(WeChat)

13719286088(WeChat)

粤公网安备 44011102000800号

粤公网安备 44011102000800号