- HTAC

- Regenerative burner requiring reversing fuelIntegral self-regenerative burnerRegenerative with non-reversing fuelRegenerative burnerTop mounted integral regenerative burner

- Complete set of industrial furnace

- Aluminum melting furnace seriesTilting reflector furnaceRegenerative tilting furnaceRegenerative type crucible furnaceRegenerative type shuttle kilnRegenerative type organic waste gas incinerator

- Industrial furnace accessories

- Aluminum liquid circulation mechanical pump/lifting pumpAluminum liquid lifting vacuum pumpLongxin burner controllerLongxin regenerative burner type combustion system control softwareTwo-position three-way selector valveLongxin high-quality ignition gunFuel oil gunBall-blocking brickMechanical pressed regenerative burner bodyFurnace door and accessories

Regenerative type radiation heating pipe

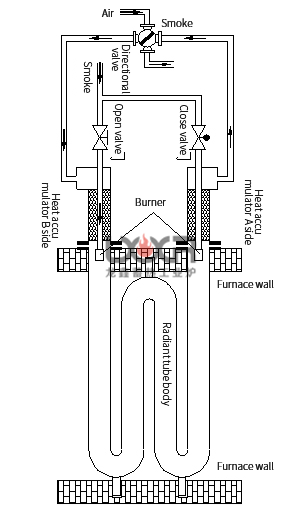

Regenerative radiation heating tube burner structure: regenerative gas radiation tube heating device has a variety of structural forms, commonly used are U-type, W-type, mainly composed of tube, burner and regenerator. The tube body is the key component which radiates the heat energy released from the combustion of gas to the material. It has good heat resistance, high thermal conductivity, strong high temperature oxidation resistance, small thermal expansion coefficient, high structural strength and good sealing performance. The burner is the core of the radiation tube heating device, which controls the power, temperature distribution, thermal efficiency and service life of the radiation tube. The regenerator is an important component for recovering waste heat from flue gas, which is used to preheat combustion-supporting air and improve the thermal efficiency of radiation tubes.

-

- Product features:

1. The regenerative HTAC gas radiation heating tube has the characteristics of high combustion efficiency, energy saving, uniform surface temperature distribution, long service life and low greenhouse gas emission.

2. Using high temperature air combustion technology, the temperature distribution in the pipe is uniform.

3, efficient recovery of waste heat, more than 80% of the waste heat recovery efficiency;

4. The honeycomb ceramic regenerator manufactured by the unique technology has the characteristics of high heat storage, fast heat transfer, good structural strength, high temperature and pressure resistance, quench and heat resistance, oxidation resistance and corrosion resistance, low resistance loss and economic durability.

The 5 and four way reversing valves adopt the high frequency switch valve to eliminate the explosion risk caused by the unsynchronized gas and air.

6, the valve's service life is more than 1 million times, and the switching time is less than 0.5 seconds. The burner adopts unique technology, which has enough combustion and less CO2 and NOx emissions.

7. Flexible PLC control system is used to automatically complete the commutation of air, flue gas and fuel, and the monitoring of flame and temperature.

-

- Product parameters:

Applicable fuels: gas and fuel;

Comparison of environmental protection: compared with the traditional radiant tube, the energy saving is 30 to 60%, which is more than 60% above the radiation heating of electric furnace.

Illustration: the working principle of regenerative radiant heating tube burner

For further information, please contact us. We will serve you wholeheartedly!

13719286088(WeChat)

13719286088(WeChat)

粤公网安备 44011102000800号

粤公网安备 44011102000800号