- HTAC

- Regenerative burner requiring reversing fuelIntegral self-regenerative burnerRegenerative with non-reversing fuelRegenerative burner

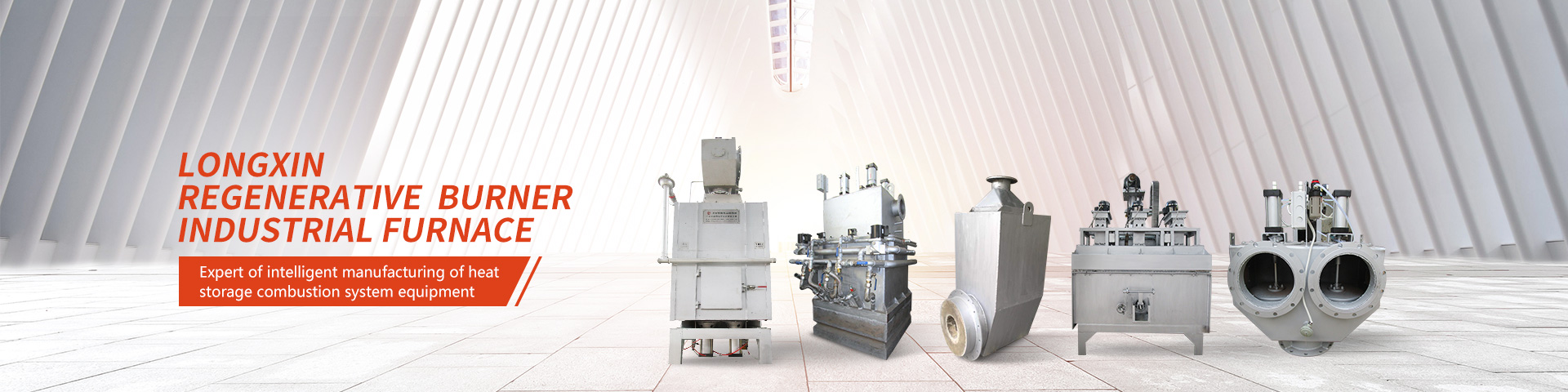

- Complete set of industrial furnace

- Regenerative aluminum melting furnace and heat holding furnaceRegenerative chamber type heating furnaceRegenerative type shuttering roasting furnaceRegenerative type heat treatment furnaceRegenerative heat treatment furnaceRegenerative type annealing furnaceRegenerative type shuttle kilnRegenerative type crucible furnaceRegenerative type radiation heating pipeRegenerative type organic waste gas incinerator

Regenerative type shuttle kiln

Shuttle kiln is used for drying, heating and firing. It is an intermittent kiln, also known as drawer kiln, which loads products on kiln trucks, pushes them into kilns, closes kiln doors and firs them. The volume of shuttle kiln is generally in the range of 2 m3-80 m3, and the firing temperature is high. The temperature of different firing products is up to 1000-1700 C. The process temperature control curve is strict. The firing atmosphere (oxidation flame, reduction flame, neutral flame) has a great influence on the quality of products.

The regenerative shuttle kiln designed and built by Guangzhou Longxin Regenerative Industrial Furnace Co., Ltd. consists of steel structure, lining, door, kiln car, regenerative combustion system and its automatic control system.

-

- Product features:

Product features: 1. The shuttle kiln body uses profiled steel as the framework, uses steel plates over 6mm as the furnace surface, and after welding each other, forms a whole with good sealing effect and less heat loss. As the steel frame structure of shuttle kiln, the outer part of the kiln is encapsulated with colored steel plates, so as to be beautiful and practical.

2. Full-fiber lining, through ingenious design, improves the insulation performance of 20% lining, reduces the heat storage loss of more than 60% lining, ensures that the surface temperature of the furnace body is less than 60 C, the energy-saving effect is more prominent, and the service life of the traditional shuttle kiln is twice as long as that of the traditional shuttle kiln.

3. The furnace door shell has good thermal insulation performance and light weight. Strong sealing between furnace door and furnace mouth, pressure furnace mouth, prevent heat overflow in furnace, ensure that the movement of furnace door is easy, safe and reliable;

4. The shuttle kiln car and kiln body are sealed with zigzag and sand sealing structure, which increases the sealing performance of kiln, reduces the temperature difference between upper and lower kilns, reduces heat loss, shortens the holding time of high fire and promotes the reduction of fuel consumption.

5. PLC regenerative combustion automatic control system control, once safety abnormalities are found, the alarm signal will be immediately activated.

-

- Product parameters:

Applicable fuels: gas and fuel;

Applicable conditions: furnace temperature above 800 C, fuel / gas. Ensure energy efficiency is higher than 25%;

Application of products: Shuttle kiln is suitable for many kinds and small batches of daily ceramics, sanitary ceramics, electronic ceramics, refractories and chemical powder materials.

Illustration: construction site of new regenerative shuttle kiln

Pictorial: all fiber regenerative shuttle kiln

For further information, please contact us. We will serve you wholeheartedly!

13719286088(WeChat)

13719286088(WeChat)

粤公网安备 44011102000800号

粤公网安备 44011102000800号