- HTAC

- Regenerative burner requiring reversing fuelIntegral self-regenerative burnerRegenerative with non-reversing fuelRegenerative burnerTop mounted integral regenerative burner

- Complete set of industrial furnace

- Aluminum melting furnace seriesTilting reflector furnaceRegenerative tilting furnaceRegenerative type crucible furnaceRegenerative type shuttle kilnRegenerative type organic waste gas incinerator

- Industrial furnace accessories

- Aluminum liquid circulation mechanical pump/lifting pumpAluminum liquid lifting vacuum pumpLongxin burner controllerLongxin regenerative burner type combustion system control softwareTwo-position three-way selector valveLongxin high-quality ignition gunFuel oil gunBall-blocking brickMechanical pressed regenerative burner bodyFurnace door and accessories

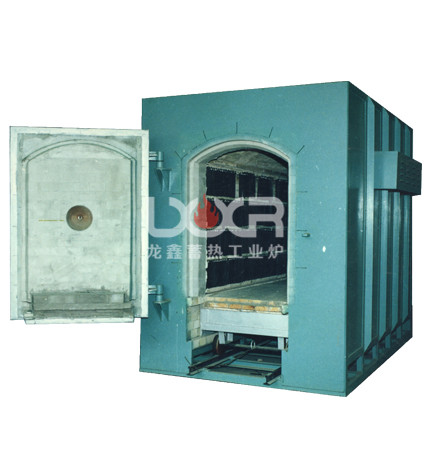

Regenerative burner type shuttering roasting furnace

Mold shell roaster, also known as shell mould preheating furnace, is suitable for the heating purposes of model dewaxing, drying and roasting heat treatment in precision casting industry. Its purpose is to heat the shell mould completed by dewaxing into the heat treatment furnace, to evaporate the wax remaining in the shell mould, and to sinter the shell mould, so as to avoid the shell mould being heated and cracked during casting. The shell mould is loaded and removed in batches from the furnace door, and periodically heated. The temperature of the whole furnace remains unchanged. The furnace area is generally less than 10 square meters.

-

- Product features:

1. Shape steel is used as the framework of the shell baking furnace body, and steel plates over 6 mm are used as the furnace surface. After welding each other, a whole body with good sealing effect and less heat loss is formed, which is used as the outer steel frame structure of the shell baking furnace.

2. Furnace lining materials can be selected according to customers'economic strength to ensure that the surface temperature of the furnace body is less than 60 C, the energy saving effect is more prominent, and the service life of the furnace is twice as long as that of the traditional shell baking furnace.

3. The door and mouth of the furnace are sealed by the advanced spring-type compaction structure and soft-edge sealing device in China, which has long service life and good sealing effect, and can effectively prevent heat spillover in the furnace.

4. PLC regenerative combustion automatic control system control, once safety abnormalities are found, the alarm signal will be immediately activated.

-

- Product parameters:

Applicable fuels: gas and fuel;

Suitable conditions: the heating temperature of the furnace is different from that of the shell mold, and the requirement is 1000 to 1400 degrees Celsius. It is divided into chamber type, trolley type, push rod type precision casting shell baking furnace and so on.

Illustration: regenerative trolley shell baking furnace

For further information, please contact us. We will serve you wholeheartedly!

13719286088(WeChat)

13719286088(WeChat)

粤公网安备 44011102000800号

粤公网安备 44011102000800号