- HTAC

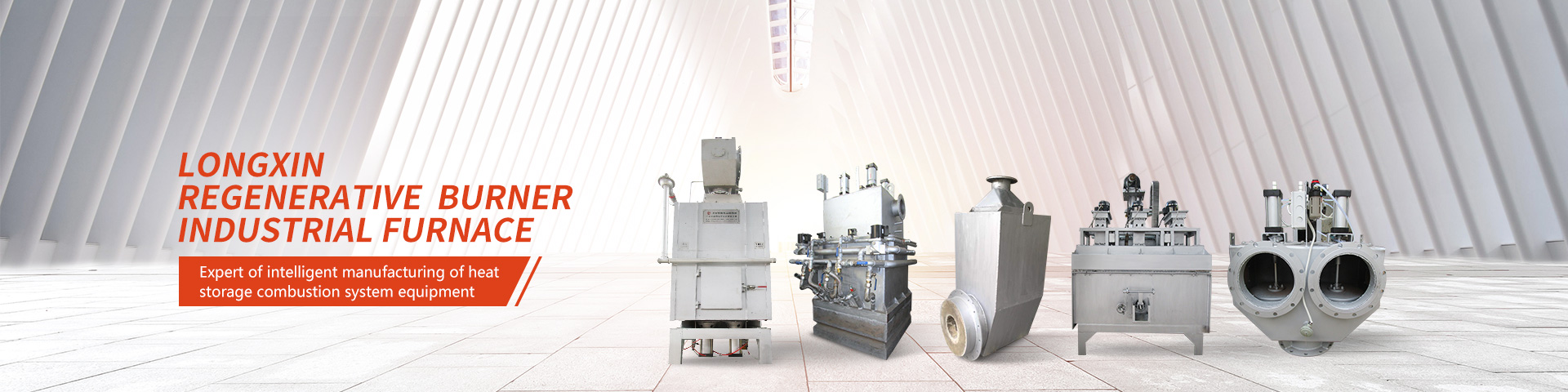

- Regenerative burner requiring reversing fuelIntegral self-regenerative burnerRegenerative with non-reversing fuelRegenerative burnerTop mounted integral regenerative burner

- Complete set of industrial furnace

- Aluminum melting furnace seriesTilting reflector furnaceRegenerative tilting furnaceRegenerative type crucible furnaceRegenerative type shuttle kilnRegenerative type organic waste gas incinerator

- Industrial furnace accessories

- Aluminum liquid circulation mechanical pump/lifting pumpAluminum liquid lifting vacuum pumpLongxin burner controllerLongxin regenerative burner type combustion system control softwareTwo-position three-way selector valveLongxin high-quality ignition gunFuel oil gunBall-blocking brickMechanical pressed regenerative burner bodyFurnace door and accessories

Runner type on-line degassing equipment

Guangzhou Longxin LXDU-T multi-rotor flow trough online degassing equipment for liquid aluminium is a product used to improve the quality of liquid aluminium and the mechanical properties of castings. The equipment is installed on the specially designed degassing groove. It is an on-line and uninterrupted degassing equipment matched with the flow groove. It is suitable for continuous casting or semi-continuous casting melting furnace with aluminium liquid flow rate of 5 to 25 tons per hour.

- Technical parameters:

1, rotor number: 1 to 6 stage rotor optional, multi-stage degassing efficiency is higher.

2. Degassing object: hydrogen in flowing liquid in the chute or degassing box.

3. Maximum liquid aluminum handling capacity: each rotor can handle 5t/h aluminum fluid.

4, mechanical and electrical characteristics: electric lifting and rotation, easy for equipment maintenance and replacement of graphite rotor.

5, degassing speed: 0~600 turn /min, the speed of digital display can be adjusted, and every 3 rotors can be independently controlled.

6. Degassing medium: industrial dry nitrogen or argon with purity of 99.996% or more, the gas flow rate of each rotor is adjustable from 0.25 to 2.5 Nm3/h, and the gas input pressure is 0.4 to 0.6 MPa (automatic alarm when the gas input is less than 0.2 MPa prompts the replacement of the gas source);

7. Degassing effect: According to the calculation of each rotor, when the inlet flow rate is not more than 5 t/h and the hydrogen content is not more than 0.35 ml/100g, the hydrogen content can be reduced to less than 0.19 ml/100g at 700-730 C. When the inlet hydrogen content is greater than 0.35ml/100g, the degassing efficiency is not less than 45%.

8. Automatic alarm and indicator lights flashing when fault occurs to remind operators.

9. The highest temperature outside the shell is less than 75 degrees Celsius.

Illustration: flow channel on-line aluminum gas degassing equipment

For further information, please contact us. We will serve you wholeheartedly!

13719286088(WeChat)

13719286088(WeChat)

粤公网安备 44011102000800号

粤公网安备 44011102000800号